Overview

Quick Details

Applicable Industries | Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Construction works |

After Warranty Service | Video technical support, Online support, Spare parts, Field maintenance and repair service |

Condition | New |

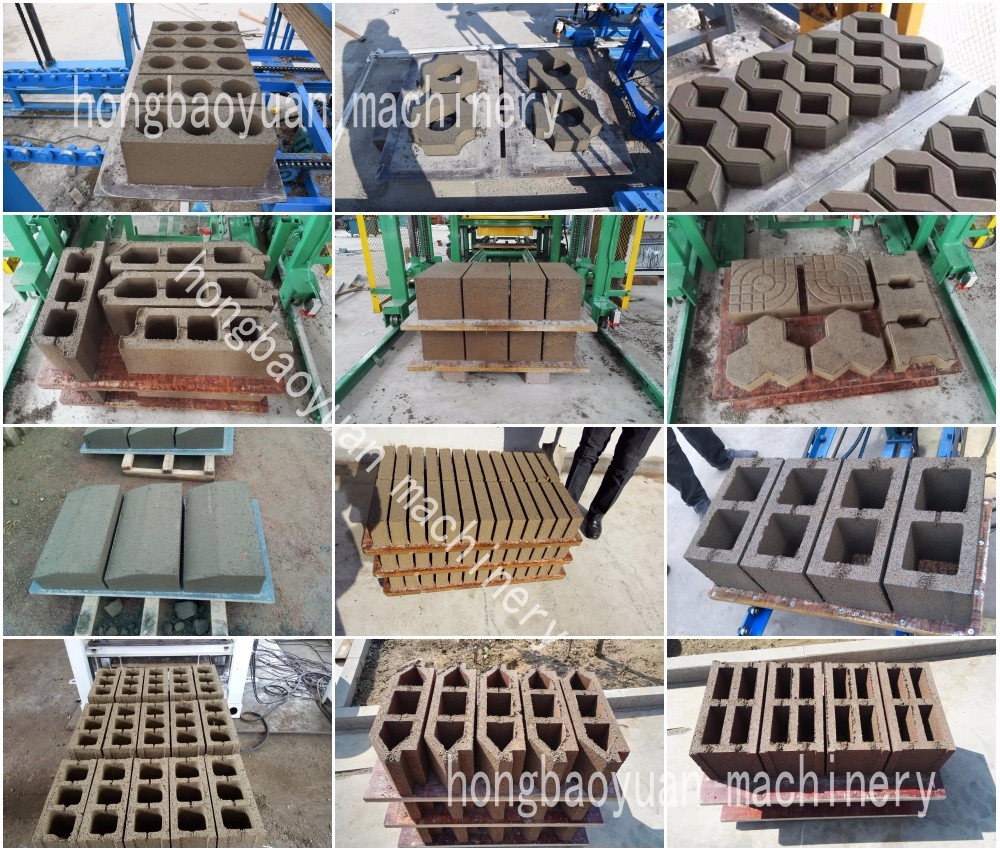

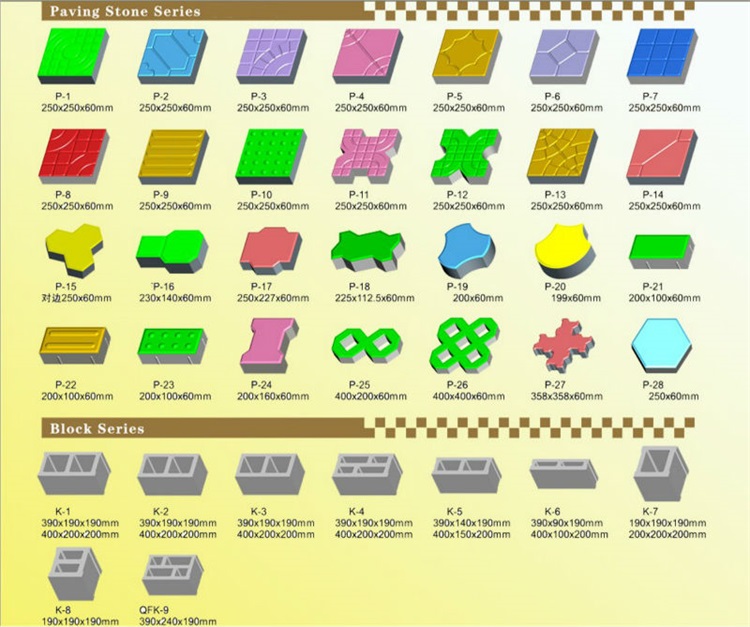

Type | Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, Other, Autoclaved aerated concrete block (AAC) |

Brick Raw Material | CONCRETE |

Processing | Brick Production Line |

Method | Hydraulic pressure |

Automatic | Yes |

Production Capacity (Pieces/8 hours) | Other, 4480 pcs/8hours, 2500 pcs/8hours, 3400 pcs/8hours, 1920 pcs/8hours, 5760 pcs/8hours, 1500 pcs/8hours, 1280 pcs/8hours, 3000 pcs/8hours, 12000 pcs/8hours, 3200 pcs/8hours, 2560 pcs/8hours, 1000 pcs/8hours, 800 pcs/8hours, 6000-10000 blocks per day |

Place of Origin | Shandong, China |

Brand Name | HONGBAOYUAN |

Voltage | 380V |

Dimension(L*W*H) | 395*210*278CM |

Certification | IS9001 |

Warranty | 1 Year |

After-sales Service Provided | Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Engineers available to service machinery overseas |

Key Selling Points | Automatic |

Brick size | 400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm |

Machinery Test Report | Provided |

Video outgoing-inspection | Provided |

Marketing Type | New Product 2020 |

Warranty of core components | 1 Year |

| Core Components | PLC, Pressure vessel, Other, Engine, Gear, Motor, Pump, Bearing, Gearbox |

Can Produce all kind of hollow and solid block,paving blocks

Advantagement:

Our equipment design advantages:

1. we use big brick machine frame are thick-walled square hole!Customers own identification method: use or use hand knock voice!

2. we all four pillar of orientation is solid steel column!Recognition methods: weighing!And guide column surface are all chromium alloy to increase wear resistance to extend the service life!Recognition methods: see, touch.And we also all the guide inner sleeve on the guide posts for alloy steel, the other all equipped with dust-proof nylon ring on both ends of the guide sleeve, can save oil filling, prevent dust from entering the increase wear resistance and prolong life!

3. machine each part we do can tear open outfit design, with convenient installation and maintenance and replacement parts!And friction on the machinery and equipment parts are all alloy steel processing!

2.QT8-15 Production line needed data:

1. Area: Workshop area: 150-200m2, all factory area 3000m2, the bigger, the better.

2. Workers : four or five

3. Ratio of raw material:cement 8%-10% sand 30%-40% stone:50%-60%,about cement :sand : stone is1:4:5.

4. hollow block weight:(400*200*200) :17KG,(400*150*200):13.5KG,(400*100*200):10KG

5. raw material consumption per day:160-170T

6. water consumption per day:3%-5% of raw material

7 blocks: can make all kinds of hollow and solid blocks, the pressure hollow blocks is about 8-10Mpa, solid is about 10-12Map. Can be widely used in low walls .

8.how to cure the bocks: in very hot area, about many hours can be stacked from the pallets, in the first 5-7days must spray water to cure, about 7 days can be sell. in usual area, about one day later can be stacked from pallets, in the first 5-7 days must spray water to cure. About 14 days can be sell.

According to the production output,It needs to match with JS750 Mixer machine.

About the data of JS750 Mixer machine in the below:

NO. | ITEM | DATAS |

01 | Charge volume(L) | 1200 |

02 | Discharge volume(L) | 750 |

03 | Max diameter | 80/60 |

04 | Capacity(m3/h) | >35m3/h |

05 | Rotate speed of blades (r/min) | 31r/min |

06 | Dimension (L*W*H) | 5980*2300*6260 |

07 | Total weight(kg) | 6800 |

08 | Discharge height(mm) | 1500 |

09 | Mixing motor power | 30kw |

10 | Lifting motor power | 7.5kw |

11 | Pump motor | 1.1kw |

3.some other statement

This QT8-15 block machine for sale is automatically .It made up of host machine,stacker machine,hydraulic station plaform,PLC systerm control Case,JS750 Mixer machine,one set of mold,3 trolleys . All of these need one 40 FEET container to ship to your country.

Besides, we supply after-sale service overseas.After the machines arrives in your place, we supply the installation service if you need helps. we ensure that you produce bricks normally.

I think that giving your best service is our duty. Sincerely willing to cooperate with you.